Quando você trabalha com um fabricante de roupas de banho personalizado, o MOQ afeta o preço e a qualidade. AMOQ alto, Tais como300 unidades, Reduz o custo por peça e ajuda a manter a qualidade consistente. Escolher um MOQ baixo permite que você experimente novos designs com menos risco, mas geralmente resulta em preços mais altos e menos opções de tecido. Relatórios da indústria sugeremBalanceamento MOQÉ a chave para controlar os custos, selecionar os tecidos certos e gerenciar a qualidade. Sempre solicite amostras e discuta suas opções com seu fabricante de roupas de banho personalizadas para garantir que sua roupa de banho atenda aos padrões da sua marca.

Principais Takeaways

Quando vocêEncomendar mais maiôs, Cada um custa menos. Isso ocorre porque os custos de instalação e material são compartilhados por mais maiôs.

MOQs baixos ajudam pequenas marcas a testar novos designs com menos risco. Mas cada maiô custa mais e há menos opções de tecido.

Falar claramente com seu fabricante ajuda você a obterMelhores preços-A. Ele também ajuda você a obter boa qualidade e mais opções, não importa quantas você pedir.

Sempre peça amostras antes de comprar um lote. Isso ajuda você a verificar o tecido, o ajuste e a qualidade.

Certifique-se de planejar bem o orçamento e o tamanho do pedido. Isso ajuda você a equilibrar custo, qualidade e armazenamento à medida que sua marca aumenta.

MOQ na fabricação Swimwear

O que é MOQ?

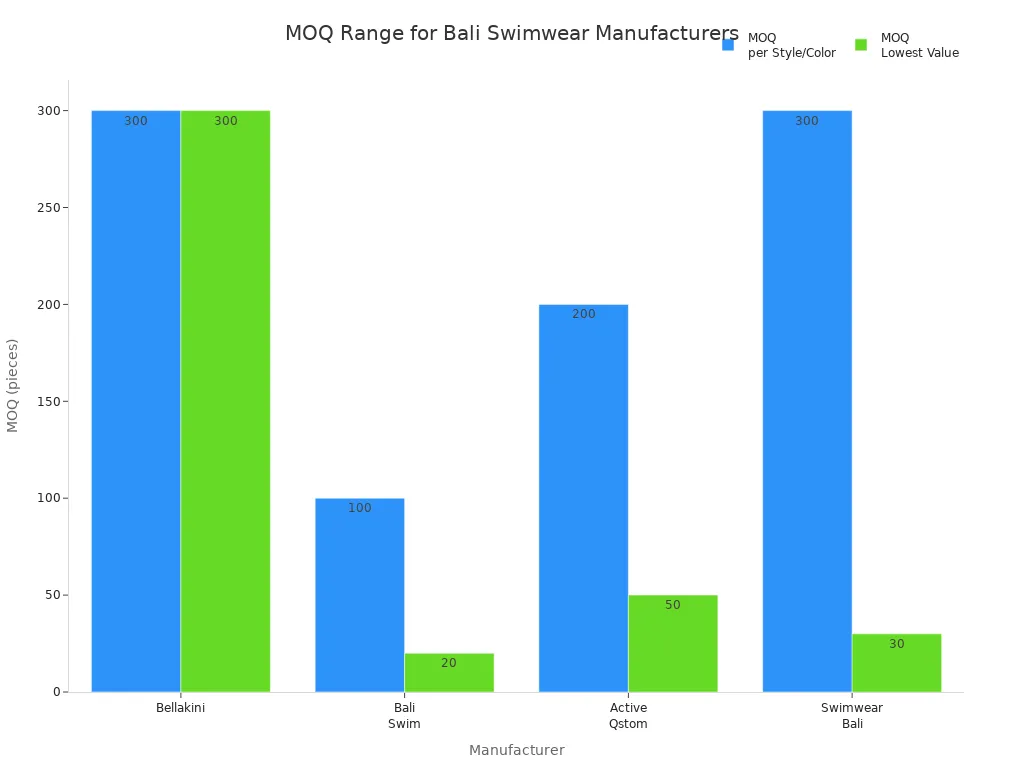

Você vai ouvir "quantidade mínima" quando falar com um fabricante swimwear personalizado. MOQ é o menor número de peças de banho que você deve comprar para iniciar a produção. Esse número ajuda o fabricante a planejar e usar bem os recursos. Por exemplo, alguns fabricantes na China precisam que você encomende800 peçasPara cada estilo e cor. Este MOQ alto funciona melhor para grandes marcas que querem muitos projetos personalizados. Em Bali, os fabricantes permitem que você encomende quantidades muito menores. SeusQuantidades mínimas do pedidoSão mais flexíveis. Você pode ver as diferenças na tabela abaixo:

Localização do fabricante | MOQ por estilo/cor | Notas |

|---|---|---|

China (produções Activewear) | 800 peças | MOQ aplica-se por estilo e cor; adequado para produção em larga escala |

Bellakini (Bali) | 300 peças | Mid-range MOQ paraBali fabricantes |

Bali Nadar | 20-100 peças | 20 peças por estilo/cor/impressão; mínimo 100 peças por categoria |

Qstom ativo (Bali) | 50-200 peças | MOQ flexível a partir de 50 peças, 200 peças padrão |

Banho Bali | 30-300 peças | 30 peças por estilo/cor/impressão; 300 peças total do pedido mínimo |

Você pode escolher um fabricante swimwear personalizado com um MOQ que corresponde ao tamanho do seu negócio. As startups costumam gostar dos fabricantes de Bali porque permitem encomendar menos peças.

Por Custom Swimwear Fabricantes Set MOQ

Os fabricantes têm várias razões para definir quantidades mínimas do pedido. Você deve saber estas razões antes que você ordem.

Os fabricantes precisam cobrirCustos configuração-A. Esses custos incluem mão de obra, equipamentos e tempo para se preparar. Se você pedir menos do que o MOQ, oO custo de cada maiô aumenta de 25% a 35%-A.

Custom swimwear fabricantes usam MOQ para fazerProdução mais eficiente-A. Quando você encontra o MOQ, os custos fixos são compartilhados sobre mais maiôs, assim que cada um custa menos.

Alguns fabricantes definem MOQs baseados em jardas de tecido. Tecidos importados ou ecológicos geralmente precisam de pedidos maiores.

Produção complexidade muda o MOQ. Projetos simples permitem que você peça menos peças. Swimwear personalizado mais complexo precisa MOQs mais elevados.

Lead times e padrões éticos também importam. Os fabricantes tentam equilibrar a qualidade, velocidade e preço, definindo MOQs.

Dica: Se você tem uma marca pequena, encontre fabricantes com MOQs flexíveis. Você pode experimentar novos designs de moda praia personalizados sem gastar muito dinheiro.

MOQ e Swimwear Produção Custos

Preço por unidade

Quando você compra swimwear personalizado, quantos você encomendar muda o preço. Se você pedir apenas alguns,Cada maiô custa mais-A. Isso ocorre porque o fabricante ainda paga pela configuração, mão de obra e tecido para cada pedido. Esses custos não mudam se você pedir muito ou pouco. Pequenas encomendas também usam preços tecido mais caro. Você paga mais por cada metro de tecido. Cada maiô em uma pequena ordem tem que cobrir mais da máquina e verificar os custos de qualidade.

Aqui está uma tabela que mostra como o custo por maiô muda com o tamanho do pedido:

Quantidade do pedido | Faixa de preço por unidade | Explicação |

|---|---|---|

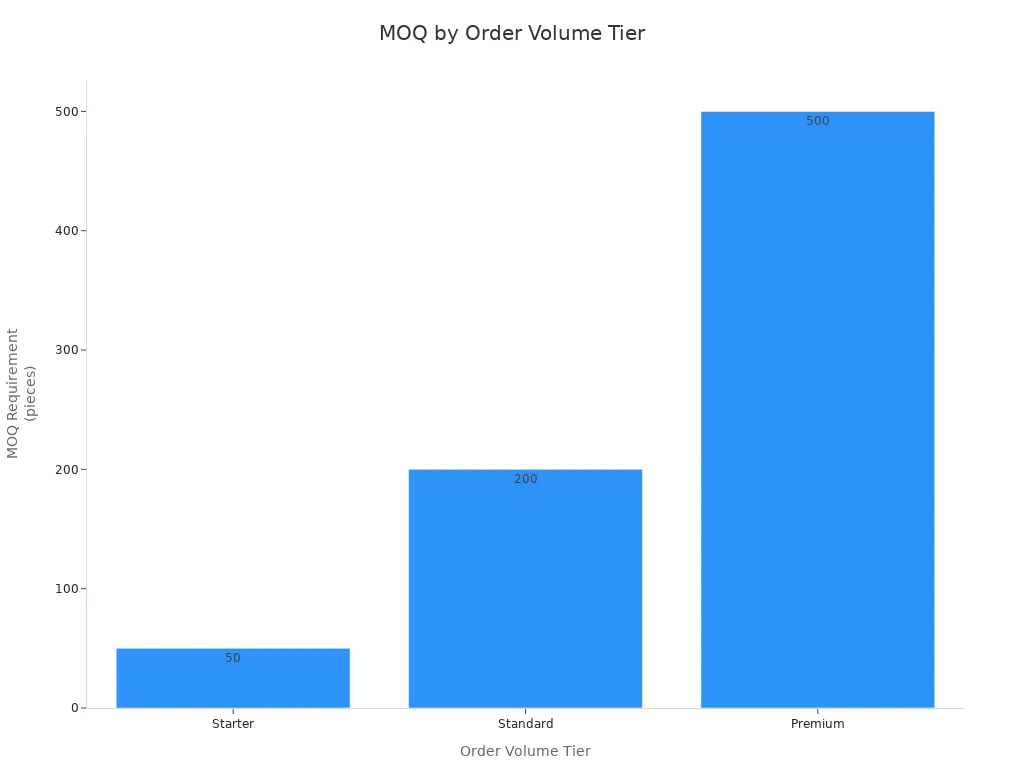

Baixo MOQ (sob 100 unidades) | 20 $-30 $ + | Os custos são mais altos devido à menor eficiência, tecido caro e taxas de configuração |

MOQ alto (ao redor 300 unidades) | 9 $-20 $ | Custos são menores porque fazer mais maiôs economiza dinheiro |

Você pode ver que encomendar menos de 100 maiôs custa$20 a $30 ou maisPara cada um. Se você pedir cerca de 300, cada maiô custa US $9 a US $20. Isso significa que você paga US $10 a US $20 a mais por cada maiô se você pedir um pequeno lote. Fabricantes descobrir o preço para cada maiô porAdicionando tecido, guarnições, mão de obra e embalagem-A. Eles também adicionam taxas de configuração e qualidade. Se você pedir amostras, elas custam cerca de três vezes mais do que o preço a granel. Isso ocorre porque fazer apenas alguns não é tão eficiente quanto fazer muitos ao mesmo tempo.

Economias de escala

Se você pedir mais maiôs, você economiza dinheiro em cada um. Isso é chamadoEconomias de escala-A. Quanto mais você pedir, menos os custos de cada maiô. Fabricantes gostam de grandes encomendas porque é mais barato fazer muitos ao mesmo tempo. Eles podem comprar muitos materiais de uma só vez e usar máquinas por mais tempo. Isso espalha os custos fixos por mais maiôs. Você obtém um preço melhor, e seus custos vão para baixo.

Pedir mais maiôs permite obter preços por volume.

Grandes encomendas ajudam você a gastar menos em cada maiô.

Fabricantes como grandes encomendas porque economiza tempo e reduz o desperdício.

Mas você precisa fazerPense no seu dinheiro e armazenamento-A. Grandes encomendas significam que você paga mais adiantado eDe um lugar para guardar seus maiôs-A. Se a sua marca é pequena, você pode quererComece com um MOQ mais baixo-A. Você pode pedir mais conforme suas vendas crescem. Algumas marcas compartilham pedidos com outras para alcançar o MOQ e obter melhores preços.

Orçamento para MOQ

É importante planejar o seu orçamento para fazer roupas de banho. Você deve definir um orçamento adequado ao tamanho do seu negócio. A maioria das marcas gasta entre US $5.000 e US $30.000, Dependendo de quantos maiôs eles fazem. Você pode conversar com seu fabricante sobre MOQs flexíveis e melhores preços. Sempre planeje custos como fazerAmostras, que podem custar $75 a $400Para cada desenho. Você também precisa pagar um depósito, geralmente a metade do custo total.

Aqui estão algumas dicas para ajudá-lo a gerenciar seus custos swimwear:

Escolha materiais e lugares para fazer seus maiôs que se encaixam no seu orçamento.

Certifique-se de incluir verificações de qualidade para evitar erros e desperdícios.

Compre materiais a granel, se puder, para economizar dinheiro.

Preste atenção para quando swimwear vende melhor, geralmente maio a agosto. Planeje seus pedidos e dinheiro para esses meses.

Converse com seu fabricante frequentemente para corrigir problemas de fornecimento e discutir o pagamento.

Conheça os mínimos para cada tamanho, cor ou design.-A. Muitos fabricantes querem pelo menos 20-50 peças por estilo ou cor e cerca de 5 por tamanho. Misturar tamanhos, cores e estilos pode tornar as coisas mais difíceis e custar mais.

Use serviços do fabricante como modelagem e ajuda técnica para evitar erros.

Estude seu mercado e concorrentes para obter melhores preços de seu fornecedor.

Observação: o planejamento cuidadoso ajuda você a equilibrar seu orçamento, qualidade e opções. Se você sabe o que vai para o custo de fazer roupas de banho, você pode fazer melhores escolhas e evitar surpresas.

MOQ e Swimwear Qualidade

Opções do tecido

MOQ é importantePara os tipos de tecido que você pode escolher. Se você pedir muito, você terá mais opções de tecido. Você pode escolher tecidos melhores e ecológicos. Alguns fabricantes baixam seu MOQ para ajudar as marcas a usar materiais verdes. Outros precisam de um MOQ maior porque os tecidos especiais custam mais ou são mais difíceis de obter.

Aqui está umTabela que mostra como os fabricantes diferentes seguram opções e MOQ da tela:

Fabricante | Gama MOQ | Uso de Tecidos Premium/Sustentáveis | Impacto em MOQ e produção |

|---|---|---|---|

Grupo Vestuário Arcus | Por volta 50 | Sim, tecidos ecológicos | Produção pequena do grupo com materiais sustentáveis, mais baixo MOQ |

Bali Nadar | Cerca 100 | Sim, tecidos sustentáveis | Suporta pedidos menores de moda praia ecológica |

Reino Unido Swimwear fabricantes | MOQ alto | Sim, telas do eco | Pedidos maiores necessários, depende do tamanho da fábrica e produção escala |

Movimento MFG | MOQ baixo | Sim, tecidos sustentáveis | Pequenas corridas focadas na sustentabilidade |

Fábrica Banho Bellakini | MOQ personalizado | Sim, telas do eco | MOQ muda com estilo, orçamento e necessidades de sustentabilidade |

Se você quer tecidos reciclados ou extravagantes, pergunte ao seu fabricante sobre seu MOQ. Algumas fábricas permitem encomendar apenas 50 peças com tecidos especiais. Outros querem encomendas maiores para que valha a pena. Sempre verifique amostras de tecido antes de pedir muito. Isso ajuda você a ver a cor real, esticar e sentir.

Dica: Escolher o tecido certo com o MOQ certo ajuda você a fazer roupas de banho ótimas para sua marca.

Controle Qualidade

Qualidade controleMantém o seu swimwear olhar e sentir bem. Quando você pede muito, as fábricas usam verificações de qualidade fortes. Eles olham para tecido, costura, ajuste e cor. Eles também testam costuras e se as cores permanecem brilhantes. Isso ajuda a encontrar problemas cedo e mantém seu swimwear o mesmo.

A maioria das fábricas usa essesQualidade controle passos:

Amostragem: Você obtém amostras primeiramente para verificar o ajuste, a cor, e a tela.

Múltiplos pontos de verificação: as fábricas verificam materiais, costuras e impressões em momentos diferentes.

Amostragem aleatória: Eles escolhem maiôs aleatórios para verificar se há erros.

Qualidade controle checklist: Esta lista abrange ajuste, impressão, costuras, marca e embalagem.

Lote teste: Fábricas lavar e esfregar maiôs para ver se eles duram.

Fábricas usamFerramentas digitaisE falar com você para acompanhar cada passo. Você deve pedir fotos, relatórios e atualizações durante a produção. Isso ajuda você a encontrar problemas antes do navio seus maiôs.

Nota: Um bom controle de qualidade significa menos retornos, clientes satisfeitos e uma marca mais forte.

Consistência Produção

Consistência na produção significa que cada maiô no seu pedido é o mesmo. O MOQ muda o quão fácil é manter as coisas iguais. Com um MOQ alto, as fábricas usam boas máquinas e trabalhadores qualificados. Eles usam software de padrões, corte cuidadoso e impressões personalizadas para manter os tamanhos e cores correspondentes.

Aqui estão as maneiras fábricas manter a produção consistente:

Eles usam2D Auto CAD para padrões, Então os tamanhos estão certos.

Máquinas especiais swimwear fazer costuras fortes e bordas lisas.

Ferramentas digitais rastreiam materiais e maiôs acabados, então nada é perdido.

Amostras e maiôs teste ajudá-lo a verificar o ajuste e cor antes de grandes encomendas.

Verificações regulares em cada etapa pegam erros cedo.

Os relatórios mostram se o tecido e as cores permanecem os mesmos.

Trabalhe estreitamente com sua fábrica. Compartilhe seus designs e pacotes tecnológicos. Peça amostras de tecido e aprove-as antes de grandes encomendas. Este trabalho em equipe ajuda a manter seus maiôs iguais, mesmo com MOQs pequenos ou grandes.

Fazer pequenas quantias significa que você deve planejar bem para ganhar dinheiro. Para novos estilos e cores, pré-vendas e feito sob encomenda ajudam a planejar quantos fazer. Isso também permite que os clientes escolham estilos e tamanhos. ”-Jessica von Bargen, fundadora da JVBswim

Se você planejar suas ordens e falar muitas vezes, você pode obter bom, combinando swimwear em qualquer MOQ.

Escolhendo um fabricante Swimwear personalizado

Startups vs. Marcas Estabelecidas

O tamanho do seu negócio muda o que você pode fazer. Pequenas marcas e startups querem baixos moqs e menos risco. Grandes marcas podem comprar mais e obter preços mais baixos. A tabela abaixo mostra as principais diferenças:

Aspecto/Marca Tipo | Startups/Pequenas Marcas | Marcas Estabelecidas |

|---|---|---|

MOQ Tamanho | MOQs altos (200 + peças) | |

Impacto financeiro | Menor custo inicial, maior preço por unidade | Maior custo inicial, menor preço por unidade |

Flexibilidade | Alta flexibilidade, fácil de testar novos designs personalizados | Menos flexibilidade, mas marca e fornecimento estáveis |

Suporte do fabricante | Ajuda pessoal, amostras rápidas, pagamentos flexíveis | Ofertas de longo prazo, marca personalizada, melhores condições |

Estratégias | Ajuntamento, teste ordens, parcelas | Volume ordens, maximizar descontos |

Startups como pequenas encomendas e amostras rápidas. Eles também gostam do pagamento flexível. Grandes marcas encomendar mais e economizar dinheiro ao longo do tempo. Eles se preocupam com branding estável e negócios de longo prazo. Alguns fabricantes, como TideLine Swimwear e Arcus Apparel Group, oferecem baixos moqs. Eles dão amostras rápidas para que novas marcas possam experimentar o mercado.

Negociação MOQ

Você pode conversar com seu fabricante sobre o tamanho do pedido e preço. Diga-lhes seus planos comerciais e ideias branding. Muitos vão deixar vocêPagar mais por maiô para pequenas encomendas-A. Alguns deixam vocêPagar em partes-A. Você pode misturar estilos ou cores para atingir o mínimo. Algumas marcas se unem para conhecer o moq.

Ofereça-se para pagar um pouco mais pelo seu primeiro pedido.

Use amostras e teste ordens para verificar a qualidade antes de comprar mais.

Aguarde mais ou ordem durante tempos lentosPara melhores moqs.

Escolha tecidos e cores que a fábrica já tem para economizar dinheiro.

Fale claramente e pague a tempo para construir confiança com seu fabricante.

Bali Swim e Eros AtacadoAjudar pequenas marcas, oferecendo amostras sem moq ou mínimos baixos. Isso permite que você experimente amostras personalizadas e branding antes de fazer um grande pedido.

Equilibrando preço e qualidade

Você precisa fazerEquilibrar qualidade e custoAo escolher um fabricante. Você quer que sua marca pareça boa, mas você também precisa observar seu orçamento. Aqui estão alguns passos para ajudá-lo:

Peça por amostrasPara verificar tecido, ajuste, e branding.

Escolha fabricantes com boa qualidade verifica e comunicação clara.

Escolha tecidos melhores para conforto e resistência, mesmo que custem mais.

Verifique se o seu fabricante pode fazer mais como sua marca cresce.

Peça preços claros para que não haja surpresas.

Use amostras para testar novos designs e marcas antes de grandes encomendas.

Comece com um pequeno lote para verificar a qualidade, depois peça mais se você estiver feliz.

Moqs baixos permitem que você experimente novas marcas e designs-A. Moqs altos tornam cada maiô mais barato, mas você paga mais no início. Sempre use amostras e marca clara para fazer seu swimwear se destacar e atender às suas necessidades.

Dica: Falar claramente e ter uma marca forte ajuda você a obter o melhor preço, qualidade e flexibilidade do fabricante de roupas de banho personalizadas.

Você pode gerenciar preço e qualidade em swimwear personalizado se você sabe sobre MOQ. Siga estes passos para planear as suas encomendas: 1. Descubra quanto custa cada maiô e olhe para diferentes fornecedores-A. 2. Peça amostras para que você possa ver a qualidade. 3. Trabalhe bem com os fabricantes para obter melhores preços. 4. Adivinhe quantos maiôs você vai vender e manter o controle de seu estoqueEntão você não tem muitos de sobra. -Falar claramente ajuda a explicar o que você quer e corrigir problemas cedo-A. -Obter atualizações e ser honesto ajuda seu swimwear a ser feito da maneira certa.

FAQ

O que significa MOQ para a minha primeira ordem swimwear?

MOQ significa "quantidade de ordem mínima."Você deve encomendar pelo menos esse número de maiôs para iniciar a produção. Se você pedir menos, o custo por peça sobe. Pergunte sempre a seu fabricante sobre seu MOQ antes que você planeie sua ordem.

Posso misturar tamanhos e cores para atender o MOQ?

Muitas vezes você pode misturar tamanhos e cores para alcançar o MOQ. Alguns fabricantes permitem que você divida seu pedido entre diferentes estilos. Sempre verifique as regras para cada fábrica. Isso ajuda você a oferecer mais opções aos seus clientes.

Dica: Pergunte ao fabricante se você pode combinar estilos ou cores para atender ao mínimo.

Como um MOQ baixo afeta minhas escolhas do tecido?

ABaixo MOQPode limitar as opções do tecido. As fábricas podem não oferecer tecidos especiais ou ecológicos para pequenas encomendas. Você pode precisar escolher entre o que eles têm em estoque. Sempre solicite amostras antes de decidir.

Será um MOQ maior melhorar a minha qualidade swimwear?

Um MOQ mais alto significa frequentemente melhor controle da qualidade. As fábricas usam mais cheques e melhores máquinas para grandes encomendas. Você ganha maiôs mais consistentes. Se você quiser qualidade superior, considere encomendar mais peças.

Nota: A boa comunicação com seu fabricante ajuda você a manter a qualidade alta em qualquer tamanho do pedido.